- Beranda

- About us

- Jadwal Training 2024

- Registrasi

- Training

- Kategori

- Pilih Kategori

- Pilih Kategori

- Mechanical

- Minyak dan Gas Bumi (Migas)

- Motivasi – Personal Development

- PLC – DCS – Microcontroller

- Port / Pelabuhan – Marine – Pelayaran / Shipping

- Prapurnabakti – Prapensiun

- Procurement / Pengadaan Barang & Jasa

- Sales – Marketing / Pemasaran – Bisnis

- SDM – HRD – GA

- Tambang / Mining – Mineral – Batubara

- Welding / Las

- Cari Jadwal Training

- Our Customer

- News

Menu

TRAINING RELIABILITY CENTERED MAINTENANCE (RCM)

Pelatihan RCM

Tingkatkan pemahaman Anda tentang konsep-konsep Reliability Centered Maintenance dan raih manfaatnya untuk perusahaan Anda! Jadilah peserta dalam training kami dan temukan cara untuk meningkatkan efisiensi operasional melalui strategi pemeliharaan yang cerdas dan terarah.

Latar Belakang

Untuk menanggulangi dan/atau memperlambat terjadinya proses penurunan fungsi dari peralatan atau sistem, perlu dilakukan suatu tindakan yaitu tindakan perawatan. Tindakan tersebut lebih cenderung ke arah mempertahankan dan/atau mengembalikan kondisi peralatan atau sistem tidak terlalu jauh berbeda dari kondisi awal.

Untuk menentukan kemungkinan peralatan atau sistem untuk tetap beroperasi secara terus menerus menjalankan fungsinya (pada kondisi lingkungan secara spesifik dan dalam jangka waktu tertentu) tanpa mengalami kerusakan adalah dengan cara menentukan ukuran kinerja peralatan atau sistem, yang sering disebut dengan keterandalan (reliability).

Keterandalan suatu peralatan atau sistem merupakan peluang atau probabilitas peralatan akan berfungsi sebagaimana mestinya sampai jangka waktu tertentu dan dalam kondisi lingkungan spesifik. Dari kondisi peralatan “baik” ke kondisi “rusak” tidak dapat diketahui dengan pasti. Untuk mendukung sistem produksi yang memadai diperlukan tenaga kerja yang handal atau peningkatan keahlian tenaga kerja profesi Reliability Centered Maintenance.

Tujuan Mengikuti Training RCM

- Untuk memahami Reliability-Centered Maintenance (RCM) sebagai dasar penerapan manajemen pemeliharaan atau sebagai alat bantu untuk manajemen biaya dan sebagai bagian dari manajemen proyek.

- Memahami filosofi pemeliharaan berdasarkan generasi ketiga dari generasi pemeliharaan sebelumnya yaitu: generasi pertama (breakdown maintenance) dan generasi kedua (preventive maintenance)

- Untuk menghindari kegagalan total dengan mengetahui kegagalan seperti apa yang akan terjadi.

- Untuk memahami akar penyebab mekanisme kegagalan

- Untuk meminimalkan biaya pemeliharaan dan mengoperasikan peralatan hingga kapasitas maksimum

- Untuk meningkatkan output dan meningkatkan produktivitas fasilitas yang ada

- Untuk mendapatkan peralatan pabrik yang handal, efektif dan efisien

Sasaran Training RCM

Setelah mengikuti pelatihan ini, peserta diharapkan mampu:

- Memahami dan menjelaskan konsep dasar RCM

- Menjelaskan fungsi keterandalan

- Menjelaskan laju kerusakan (kegagalan)

- Menjelaskan distribusi teoritik keterandalan

- Menjelaskan model laju kerusakan

- Menjelaskan cara mengestimasi keterandalan

- Menjelaskan cara penentuan fungsi keterandalan

Manfaat Mengikuti Training RCM

Peningkatan Keandalan Sistem: Training RCM memberikan wawasan mendalam tentang cara menganalisis risiko dan kritisitas peralatan, memungkinkan pemilihan strategi pemeliharaan yang sesuai untuk meningkatkan keandalan sistem.

Efisiensi Operasional: Dengan memahami konsep RCM, para peserta dapat merancang program pemeliharaan yang lebih efisien, mengurangi downtime, dan meningkatkan ketersediaan peralatan.

Pemahaman Mendalam tentang Peralatan: Melalui pelatihan ini, profesional dapat memahami karakteristik dan kebutuhan peralatan dengan lebih baik, memungkinkan mereka untuk merancang strategi pemeliharaan yang tepat.

Optimasi Biaya Pemeliharaan: Analisis cost-benefit yang diajarkan dalam training RCM membantu perusahaan untuk mengoptimalkan alokasi sumber daya, mengurangi biaya pemeliharaan yang tidak perlu, dan meningkatkan efisiensi pengeluaran

Cakupan Materi Training RCM

1. What is Reliability-Centered Maintenance (RCM)?

a. Fundamental change of maintenance philosophy

b. Maintenance and RCM

c. Basic idea of RCM

d. RCM implementation

e. RCM achievement

2. Plant Registration

a. What is Plant Registration?

b. What is equipment?

c. How to number the asset?

d. What kind of information has to be registered?

e. How to compile plant registration?

3. Function and Failure

a. Function and standard performance

b. Malfunction

c. Failure mode

d. Failure effects

e. Failure Consequences

f. Hidden failure consequent

g. Safety and environment consequent

h. Operational consequent

i. Summary

4. Preventive Actions

a. Engineering feasibility

b. Life time dependable failure

c. Scheduled restoration

d. Scheduled replacement

e. Life time undependable failure

f. Scheduled condition monitoring

g. Selection of preventive actions

5. Defaults Actions

a. Scheduled efforts to find failure

b. Non Scheduled maintenance

c. Re-designing

d. Lubrication

e. Zone inspection and walk-around check

6. RCM Decision Diagram

a. Effort and consequent integration

b. RCM decision making process

c. Filling out decision sheet

7. Plan, Organize and Control Proposed Tasks

a. Task grouping

b. Planning system and maintenance control

c. Failure report

d. Various Failure and its History

e. Failure process

f. Six failure patterns

g. Historical data

8. RCM Implementation

a. Who knows?

b. Pre-review RCM group

c. Facilitator and auditor

d. Implementation strategy

e. Short term approach

f. RCM Forever

9. Build skill in RCM

a. What is RCM Achievement?

b. Result of RCM analysis

c. Benefit of RCM

d. Why RCM?

10. RCM History

a. Airline enterprise experience

b. RCM at other industry

11. Case Study

DETAIL JADWAL DAN BIAYA INVESTASI TRAINING

Jadwal Training

6 – 8 Mei 2024 / 13 – 15 Mei 2024 / 20 – 22 Mei 2024 / 27 – 29 Mei 2024

Durasi Training

3 Hari

VENUE PELATIHAN

Bandung

Kagum Group Hotel, Asmila Hotel, Tebu Hotel, Amaris Hotel, Santika Hotel, Grand Setiabudi Hotel, Gas Block, dll

Jakarta

Dreamtel Hotel, Sofyatn Cut Meutia Hotel, Ibis Tamarin/ Arcadia Hotel, Asyana Kemayoran Hotel, Maxone Hotel Menteng, dll

Yogyakarta

Ibis Styles Hotel/ Ibis Malioboro Hotel/ Cavinton Hotel/ Grand Zuri Hotel, Fave Malioboro, dll

Online

Via Zoom

In House

Untuk peserta yang bergroup dari 1 perusahaan yang sama

HARGA INVESTASI / PESERTA (HARGA OFFLINE)

Rp 6.500.000

Bayar Penuh

Rp. 6.250.000

Early bid, yang membayar 1 minggu sebelumnya

Rp. 5.950.000

Untuk peserta bergroup yang terdiri dari 3 peserta atau lebih dari 1 perusahaan yang sama

Mengapa Lebih Baik di Mairodi Training?

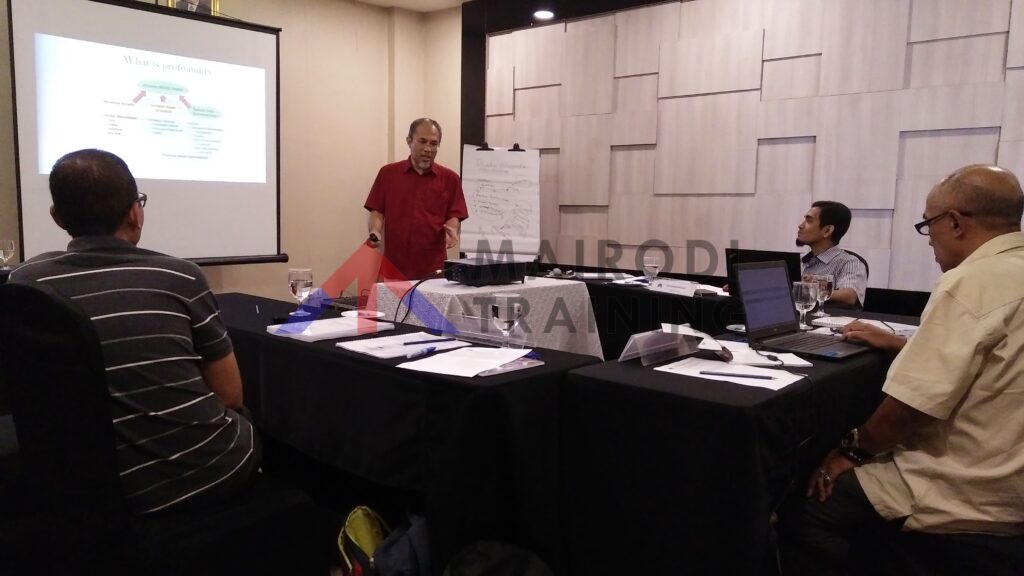

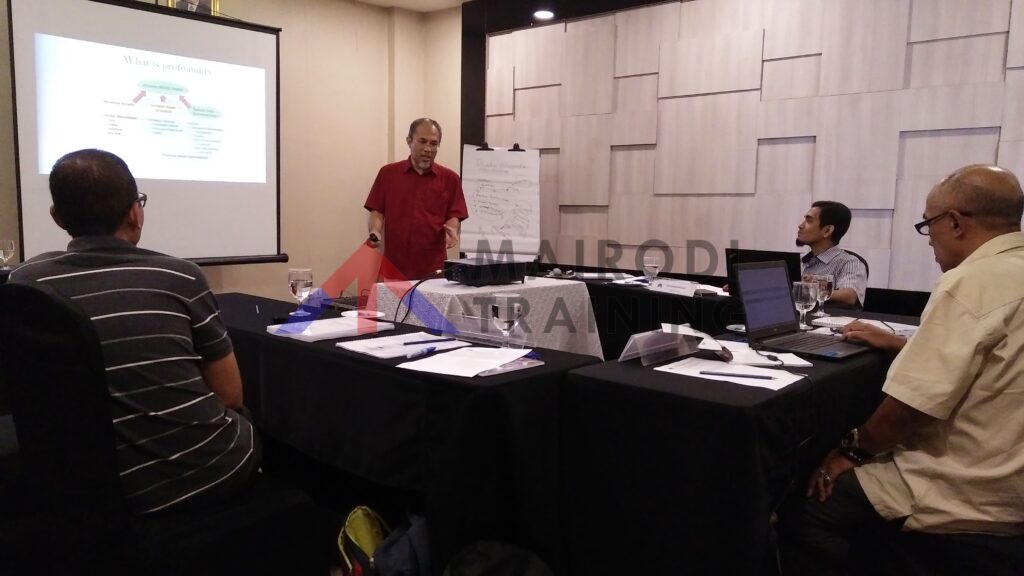

Trainer Yang Kompeten

Kami bekerjasama dengan Trainer yang kompeten di bidangnya, dengan kualifikasi Professor, Doktor, Master dan Sarjana yang berasal dari institusi terkenal di Indonesia, seperti ITB, LIPI, UI, UGM, IPB, UNPAD, STKS, BAPPENAS, BATAN dan institusi profesi lainnya

Review Positif

PT Mairodi Mandiri Sejahtera banyak mendapat respon positif dari peserta dan mendapat total rating 4,9 di Review Google

Berpengalaman

PT Mairodi Mandiri Sejahtera Sudah Berpengalaman menjadi provider Training selama 16 Tahun

Judul Training Bisa Menyesuaikan dengan Kebutuhan Perusahaan

Mairodi Training bisa membantu menyesuaikan kebutuhan pelatihan perusahaan dan Memilih Trainer yang sesuai dan kompeten di bidang tersebut

Venue Training yang Nyaman

Venue Training di Provider kami diselenggarakan di hotel – hotel berbintang yang ternama yang memiliki ruangan yang nyaman dan fasilitas yang lengkap

Biaya Investasi Training yang Terjangkau

Kami memberikan biaya Training yang terjangkau dengan berbagai fasilitas yang membuat peserta pelatihan menjadi nyaman mengikuti pelatihan di Mairodi Training

FASILITAS YANG DIDAPAT DI MAIRODI TRAINING

Modul Pelatihan

Sertifikat

T-Shirt

Ransel

Alat Tulis

Ruang Training Nyaman

Makan Siang + Coffee Break

Instruktur yang Qualified

Pencapaian Kami

0

+

Pelatihan Selesai

0

+

Judul Pelatihan

0

+

Jumlah Klien

0

Tahun Pengalaman

Ulasan dari Peserta

Saya berterima kasih kepada penyelenggara training sertifikasi Loading Master yang di lakukan oleh PT. Mairodi Mandiri Sejahtera dan para staffnya Semoga tetap berkelanjutan kedepannya.bagus dan kerenn.

Terlebih kepada Bapak Capt . RI. Triyanto. M.MAR sebagai pembicara yang luar biasa bisa memberikan ilmu yg sangat berguna untuk menunjang job saya di lapangan sebagai L/M

5/5

Instruktur nya bagus2 dan berpengalaman, pelayanan untuk peserta training bagus2. Recommended training provider

5/5

PT. Mairodi Mandiri Sejahtera adalah lembaga pelatihan yang memiliki sumber daya yang mumpuni untuk meningkatkan pengetahuan.

5/5

Our Clients

711 + Perusahaan sudah mempercayakan training karyawannya dengan kami

Previous

Next

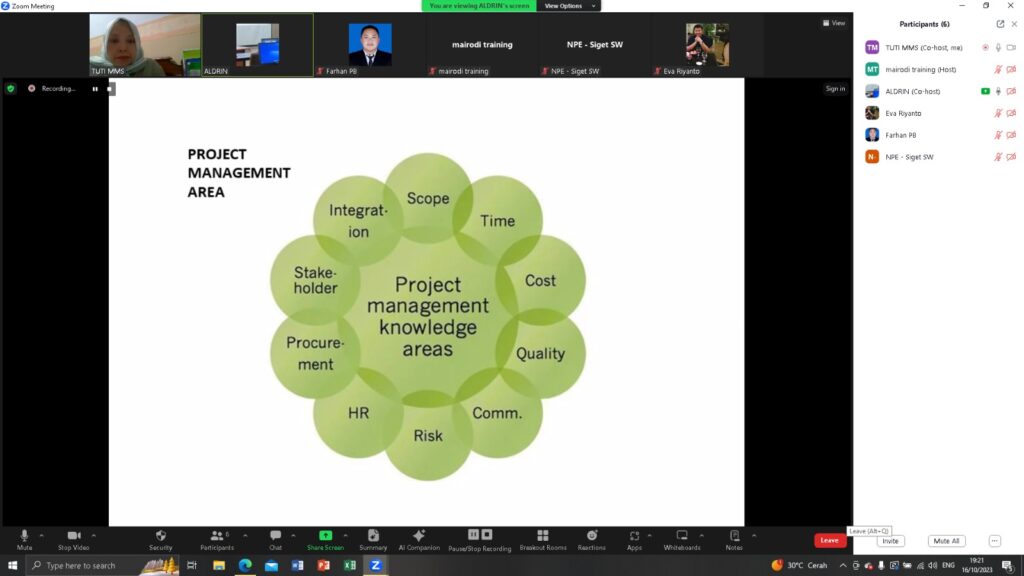

DOKUMENTASI TRAINING RCM

DOKUMENTASI PELATIHAN LAINNYA

Lokasi Kantor

PT Mairodi Mandiri Sejahtera

- Gedung Dapenpos, Jl. Phh. Mustofa No.35, Neglasari, Kec. Cibeunying Kaler, Kota Bandung, Jawa Barat 40124

- Follow kami:

TENTANG PT MAIRODI MANDIRI SEJAHTERA

Assalamu’alaikum Wr. Wb,

Salam Sejahtera,

Selamat memasuki Tahun 2024, semoga menjadi tahun kesuksesan buat kita semua!

Menjumpai semua rekan-rekan insan pembangunan Indonesia. Kami dari PT. Mairodi Mandiri Sejahtera (MMS) Training, Consulting & Engineering Services, sebagai institusi professional yang bergerak di bidang jasa training, consulting dan Engineering Services dengan bangga dan senang hati bekerja sama dengan saudara-saudara semua dalam membangun bangsa Indonesia dengan cara peningkatan, pengembangan dan pembangunan Sumber daya manusia(SDM), yang pada akhirnya akan meningkatkan performansi kerja Bangsa secara keseluruhan dan mempercepat terwujudnya Indonesia yang sejahtera dan makmur.

Kami sebagai institusi professional berusaha keras memberikan pelayanan yang maksimal dengan personel yang mengerti kebutuhan pasar dan didukung oleh instruktur-instruktur kami yang memahami dan pakar di bidangnya masing-masing dengan kualifikasi Professor, Doktor, Master dan Sarjana yang berasal dari institusi terkenal di Indonesia, seperti ITB, LIPI, UI, UGM, IPB, UNPAD, STKS, BAPPENAS, BATAN dan institusi profesi lainnya.

Kami mengerti akan kebutuhan pasar atau patner kami, yaitu kami memberikan training dengan muatan yang efektif, dengan keseimbangan kepentingan teoretikal dan praktikal sedemikian sehingga peserta merasa antusias dan nyaman berada di dalam kelas maupun workshop.

Berdasarkan tempat, kami menyelenggarakan training yang dilaksanakan di Hotel berbintang dan kami juga bersedia melaksanakan training inhouse. Berdasarkan schedule, kami menyelenggarakan training yang sudah kami atur jadwalnya(scheduled training) dan bisa juga pada waktu lain yang disepakati bersama (Customized training), termasuk judul training baru.

Jenis training yang kami selenggarakan mencakup seluruh range kebutuhan real yang ada di kantor-kantor, di pabrik-pabrik, di industri-industri, di tambang-tambang dan lain-lain dengan tema dari persoalan teknikal, non teknikal sampai persoalan sosial dan humaniora.

Kami hadir untuk memberikan service yang terbaik buat ANDA !…….